Introduction:

Increasing pressure on municipal stormwater infrastructure—driven by urban expansion, dense land development, and shifting precipitation patterns—has prompted many Canadian municipalities to shift part of the stormwater management responsibility to developers and builders. As a result, building bylaws increasingly mandate the capture and reuse of rainwater to reduce the burden on public systems while promoting sustainable water use practices

However reusing rainwater is not as straight forward as it may initially seem. Various regulations and standards may apply and require different types of water treatment to safely re-use the water, depending on the application. The key standards include CSA Standard B128.1-06/B128.2-06, CSA B805 as well as many references in building codes and municipal bylaws.

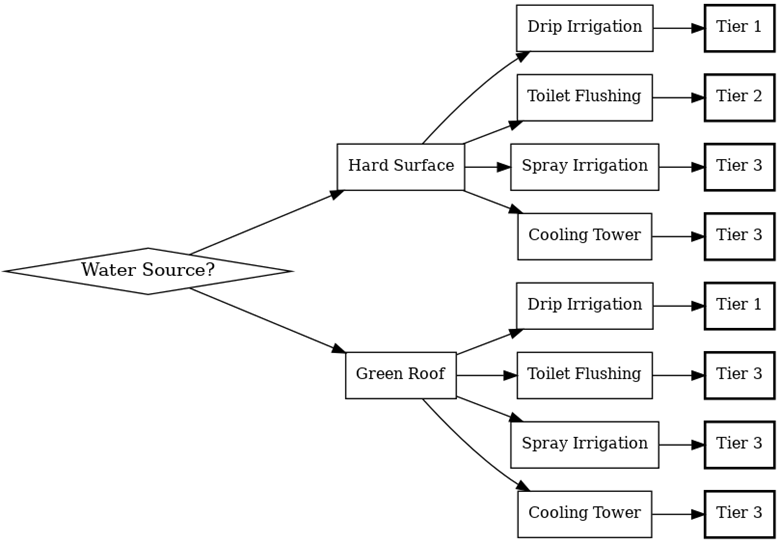

The end use of the rainwater will drive decision-making related to water treatment. The difference between drip and spray irrigation drives different needs for overall water quality, as the potential exposure to humans changes depending on the use. Similarly, the source of the rainwater, be it from hard surface roofs, or through a green roof, will drive different types of treatment trains prior to it’s ultimate use.

Key System Components and Their Roles:

A typical rainwater harvesting system involves various key components, consisting of a catchment area, a conveyance system, pre-filter devices, a storage tank, a distribution system, and an overflow system.

The catchment area is the surface on which precipitation falls directly, usually a rooftop (hard surface) or other low-permeability surfaces (green roof) can also be included. Collected rainwater then moves through a conveyance system, usually gutters, downspouts, and pipes. Pre-filtering is an essential process in which screens, leaf eaters, and first-flush diverters remove gross debris, e.g., leaves, twigs, and bird manure, from entering storage tanks. A storage tank, usually called a cistern, is used for storing collected rainwater for future use. Tanks can be made of different materials, such as plastic, concrete, and metal, each offering different advantages and considerations in terms of cost, longevity, and suitability in various applications. A distribution system, usually consisting of pumps and pipes, distributes treated rainwater to its point of use, usually an indoor installation or an irrigation system requiring pressurization.

Chart 1 breaks down different treatment options as it relates to not only the source water but also the final use.

Chart 1 – Tier system Determination:

The various tiers demand different levels of water treatment.

Tier 1:

Thes are low-risk applications, such as drip irrigation, where contact with humans is unlikely. In this case, basic filtration is all that is required, but depending on preferences, the filters can either be a basic cartridge filtration system or a more refined backwashing filtration system.

Cartridge filter systems come with a replaceable cartridge installed into a housing. Suspended solids including clay, silt, sand and dirt are easily extracted. These filters come in a range of micron ratings (typically 50 to 1) allowing for the removal of particles of varying sizes. They are especially useful in rainwater harvesting, since they do not require backflushing for regeneration, although do require regular replacement.

Backwashing filters are tank style filters that clean themselves by reversing the flow of water through the filter media. This process, known as backwashing, removes accumulated debris and contaminants from the filter bed, allow the media to be reused. Backwashing reduces replacement needs of a typical cartridge filter, although is counterproductive in rainwater re-use applications as it reduces the efficiency of the captured water.

Tier 2:

These are moderate-risk applications, such as toilet or urinal flushing, where the contact with humans is indirect.

In addition to the filtration requirements included in Tier 1 applications, Tier 2 requires the additional step of disinfection. There are 2 common approaches to achieving this disinfection, Ultraviolet (UV) or chemical injection, which both effectively eliminates pathogens.

UV is a physical process that uses UV light to inactivate microorganisms in water by damaging their DNA. It is important to control the water clarity, intensity of UV light and exposure time to the light. The pre-filtration will help maintain adequate clarity, while sizing of the system is crucial to ensure adequate exposure time at rated flow rates. Regular system maintenance, which includes cleaning of sleeves and replacing of bulbs is also critical to maintaining disinfection for the life of the system.

Chemical injection systems involve adding precise amounts of chemicals to water for various treatment purposes. Chlorine and Hydrogen Peroxide are the two most common additives. These are effective at oxidizing iron, bacteria and hydrogen sulphide. The components of this system include a chemical feed pump, storage tank and an injection point to ensure accurate and controlled dosing.

Tier 3:

Lastly, these are high-risk applications, such as spray irrigation, where the potential for aerosolization or direct human contact are high. These systems include the treatment options presented in both Tier 1 & Tier 2 systems, while adding ozone disinfection at the end of the treatment train.

Ozone (O3) is a potent oxidant and disinfectant used in water treatment. Generated on-site, this unstable gas effectively eliminates bacteria, viruses and other microorganisms by disrupting their cell structures. Ozone treatment can also oxidize dissolved minerals like iron and manganese, facilitating their removal through filtration. Additionally, it helps in reducing sulfur, tastes and odours in water. A key advantage to ozone is that it decomposes into oxygen, leaving no harmful chemical residues. Some backwashing filters are known to provide similar results to ozone, but require the consumption of clean water to regenerate the filter, thus minimizing the efficiency of the rainwater harvesting system.

Conclusion:

Rainwater harvesting presents a compelling opportunity to address the increasing demand for alternative water sources, particularly in the face of mounting pressures on freshwater supplies. However, the safe and effective reuse of rainwater requires careful planning, rigorous treatment, and adherence to established regulatory frameworks.

Through a structured tier system, this article has outlined how the combination of source water type and end-use application determines the appropriate level of treatment required. Tier 1 applications, involving low human contact risk, demand basic filtration; Tier 2 applications, such as toilet flushing, require additional disinfection; and Tier 3 applications, where aerosolization or direct human contact are possible, necessitate the most advanced treatment processes, including ozone disinfection.

By following the decision framework and treatment strategies detailed herein, designers, engineers, and building owners can confidently develop rainwater harvesting systems that are not only compliant with applicable standards such as CSA B128.1-06/B128.2-06 and CSA B805, but that also deliver reliable and safe water reuse solutions. Careful selection of system components, routine maintenance, and proper design will maximize the environmental, economic, and operational benefits of rainwater harvesting while ensuring the health and safety of users.

Properly implemented, rainwater harvesting can serve as a sustainable, resilient component of modern water management strategies — a necessary step toward preserving freshwater resources for future generations.